When it comes to developing innovative electronic devices, an electronic prototyping company plays a vital role in transforming ideas into tangible products. PCB Prototyping (see PCB benefits) is an essential step in the product development cycle, allowing engineers to test and refine their designs before moving into large-scale production.

What is PCB prototyping?

PCB prototyping is the process of getting the preliminary versions of electronics that will be part of a final product. The PCB.

Why is PCB prototyping necessary?

PCBs (Printed Circuit Boards) serve as the backbone of any electronic device, providing a platform for connecting and integrating various components, such as microcontrollers, resistors, capacitors, and sensors.

If you are planning to develop a new product, you need to validate the features you want it to have by creating a prototype circuit. Thanks to this, you or your electronic product developers team can validate the technical characteristics, identify potential issues, and make necessary adjustments early in the development process.

PCB Prototyping offers several key benefits

Design Validation

Prototyping allows engineers to test the functionality and performance of the circuit boards. It helps them identify design flaws or compatibility issues, enabling necessary refinements before production.

This process is crucial for guaranteeing a good hardware prototype, which will depend on the reliable PCB prototyping process.

PCB prototyping takes care of your budget

Detecting and resolving design flaws during the PCB prototype stage helps avoid expensive modifications or recalls in later development phases.

If you don’t take care of the initial design and development of electrical components, you will have technical problems in the future when the prototype is much more advanced.

Bear in mind that PCBs have lower costs than traditional circuit boards. Thanks to its printing process, you avoid spending thousands of dollars in complex wiring.

Great PCB prototype design means improved product quality

PCB prototypes facilitate thorough testing and optimization, leading to enhanced product quality and customer satisfaction. The most successful companies that launch different products into the market have gone through several iterations and innovation of their devices.

This means they have made several PCB prototype iterations to guarantee a great product and reliability of the promised features (see IoT device examples).

The PCB Prototyping Process

If you are not sure how to start with a prototype, we can give you some prototype examples to get you started. In this article we want to talk about a specific part of the prototyping process, which is prototyping circuit boards.

At DeepSea Developments we follow a comprehensive and streamlined process to deliver high-quality PCB prototypes:

1. Design, evaluation and consultation

After the first meeting, signing the NDA and knowing the requirements of your project, our expert engineers will evaluate your PCB design files (if you already have them).

The idea with this is to ensure these files meet the necessary specifications for the PCB prototyping. We offer free consultations to address any design concerns and provide recommendations for optimization.

If the entrepreneur or the startup already has a previously designed PCB, we could also analyze it and test it, trying to look for improvements or to confirm the required features are being met in the current PCB design. In fact, we have helped many clients who run into obstacles with their PCB design and development, and our engineers have been able to help them overcome such difficulties in the technical aspect of the PCB prototype.

2. Material selection

The next part of the PCB prototyping process is to select the appropriate materials for your PCB. It is necessary to consider factors such as board thickness, substrate type, copper weight, sensors to be used, microcontrollers, and surface finish. Our extensive knowledge and industry expertise help us choose the optimal materials for your specific project requirements.

3. PCB prototype manufacturing

Using state-of-the-art equipment and advanced manufacturing techniques, we make your PCB prototype with precision and attention to detail. For instance, if you need a rigid PCB, we could do the prototyping of circuit boards with the help of a CNC high precision machine.

On the other hand, if you need help with flexible PCBs, we can also build the prototype and manufacture it.

Our manufacturing processes adhere to industry standards, ensuring the highest quality and reliability.

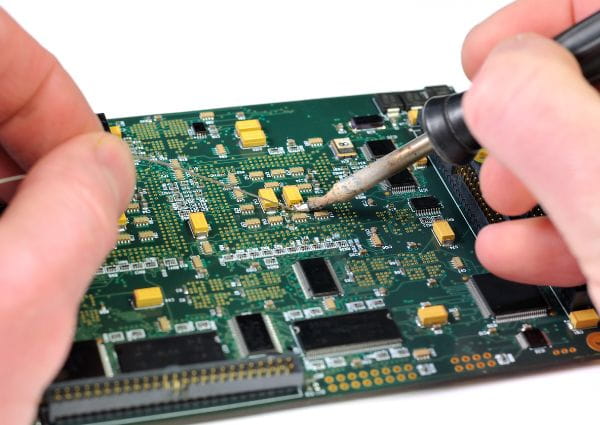

4. Assembly and component integration

If your prototype requires component integration, we offer comprehensive assembly services. Our experienced technicians handle surface-mount and through-hole component soldering, ensuring accurate placement and reliable connections.

We can also deliver all schematics that will be necessary for the future manufacturing process.

5. Testing and quality assurance

Every PCB prototype undergoes rigorous testing and quality assurance procedures. We employ advanced testing methodologies to verify functionality, electrical performance (see ESP32 chip), and signal integrity. We count on agile hardware development methodology for making incremental improvements.

Our commitment to quality by using scrum methodologies ensures that your prototype meets or exceeds your expectations.

Getting started with PCB prototyping

In summary, if you are just getting started with the printed circuit board (which will be the brain of your device), to kickstart the development of your PCB prototype, we require the following:

- Accurate PCB design files, including schematics and layout data.

- Clear specifications and requirements for the prototype.

- Any specific components or materials you prefer to be used.

- Communication regarding your project timeline and budget.

By providing this information, we can collaborate effectively and deliver a PCB prototype that aligns perfectly with your vision and goals.

Since we have helped many customers providing hardware development service, we know the struggle of many people that are trying to build their first PCB prototype. That’s why we offer a customer-centric approach to deliver top quality prototypes and meet the expectations of the customers.

If you need PCB prototyping, we invite you to contact us by clicking on the button below and book a free consultation.