The industrial IoT (IIoT) is giving companies new ways to automate their operational processes. Though a lot of data can be gathered, not everyone knows what are the benefits of these technologies. If you are in charge of a company and you want to start integrating IoT devices, you should analyze the top 5 industrial IoT applications that can take your business to a whole new level.

Of course, there are many IoT devices examples out there, but they are usually for home applications and making regular tasks easier. Let’s see what´s going on in the IIoT area.

IIoT applications for industries

The Internet of Things allows users from any area to gather information. Not only do people who work out or want to stay fit benefit from these devices, but companies have understood that being able to gather and analyze information is a big advantage in driving digital transformation.

This era values information as never before. But not everyone is ready to see its importance. Many alternatives arise from accessing new data: using it as a source for fixing problems, increasing performance, keeping control of inventory, and innovation. Check the following IIoT applications on which companies can rely to improve their competitiveness thanks to the Internet of Things.

1. Improvement of productivity

Among the most important industrial IoT applications, is the gathering of data. It becomes even more useful when a company analyzes it properly. So, IoT devices must work as an ally to improve the productivity of the companies.

How can this be done? Through data. If you install sensors that can measure the temperature, humidity, vibration, and current of your machinery, you will be able to know at what capacity and under what conditions you can, for instance, produce more, faster, and without risking your assets’ performance.

If you keep IoT devices gathering data from these machines, you can come up with great ideas to improve the efficiency of the equipment.

The workers you have in the company will also increase their productivity since they will know what machines may need assistance, they would be able to control them remotely by using software (This can save thousands of dollars for the company since they won’t have to travel to other cities to do maintenance). Also, the workers can dedicate themselves to new tasks that can benefit the company in different ways; innovation processes, new raw materials, and new technology adoption; see the pros and cons of facial recognition.

IIoT also helps companies to automate production deadlines and comply with delivery times.

2. Maximizes assets use

One great benefit of applying IoT to the industry is the possibility of maximizing the use of assets. Through software, companies can have a centralized system to control and monitor their workflows.

Almost every operative process of the company can be monitored, and that ensures better usage of the machinery, manufacturing, and processes.

Imagine that you can stop wasting raw material, reduce operational costs, and improve production quality, and delivery times by integrating the Internet of Things into the organization (See best practices for fleet management).

When you have access to data, you can realize why there are problems in the production chain; if there are bad storage conditions of the materials used for manufacturing, what is the quality of the finished product, how is the logistics working out, and implement new strategies for better performance.

All equipment you have under operation can also get preventive maintenance. This is a big advantage of IoT for industries since you can avoid losing money by unnecessary downtimes of equipment or repairs that will require a big amount of money (See IoT in Logistics).

3. Automation of data collection

You can never forget or underestimate the data you are able to collect thanks to IoT devices, remember your company will perform better if you use the data available to enhance the operation processes.

IoT devices allow companies to analyze historical data, compare it to the current status in real-time, and realize how well the company is performing to make informed business decisions.

If you don’t value the collection of data over time, other competitors will use that as an advantage to grow faster and innovate. This is where technologies like 5G and IoT are starting to emerge.

4. Predictive analytics

When a person or company gathers enough data from a process, product, or service, it is possible to use this to start predicting.

Through analysis of the information, you could create models and adapt them to your manufacturing processes. This way, the company will be able to produce products faster, with better quality, or by smartly reducing costs.

You could also estimate the behavior of your machinery, when it may stop working or need maintenance.

Thanks to IIoT applications, you could even create better products or services with the gathered information from the market. All data your devices are providing show how the production chain works, how often your stock rotates, and what are the technological trends in the sector to which you belong.

If you for instance discover with IoT devices that certain materials are not performing well under certain circumstances of production, you can take a step further than your competitors and look for possible alternatives that can deliver a better performance. Therefore, your competitiveness may increase in the market.

5. Improvement of Safety

Data is not only useful for improving the performance of the company in the production area, it is also necessary to prevent accidents.

By using IoT devices such as thermometers, thermal cameras, sensors, air quality monitors, and automatic fire sprinklers, the company can prevent a fire, explosion, gas leak, or flooding.

Of course, there will always be the possibility of human error when operating a machine or storing a product, but the company must use technology, data, and information for the benefit of everyone inside.

If your workers know safety is a great priority for the company, they will be more motivated, and their productivity may increase. This is also a great benefit for the reputation of the business since the company becomes more appealing to customers who know about the different protocols to guarantee the safety of its people.

Challenges of IIoT applications and adoption

Though IoT for industries is getting a lot of attention for its benefits and applications, some barriers need to be addressed to guarantee a faster adoption of these devices.

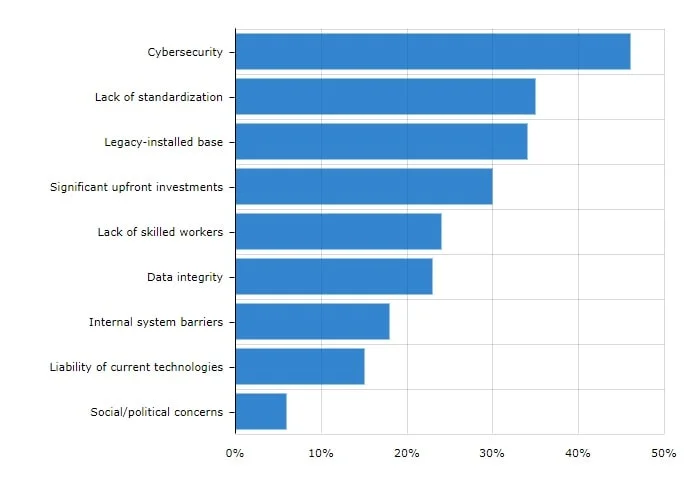

Source: Morgan Stanley-Automation World Industrial Automation Survey, AlphaWise

According to a study made by Morgan Stanley, companies have some doubts about IoT technologies because of cybersecurity, followed by lack of standardization, legacy installed base, and required investments for IoT adoption, among others.

Companies can benefit a lot from these technologies, however, they may have to get a good IoT product development company that can understand their needs and advise them properly to build IoT devices that are secure, reliable, and that contribute in the mid-term to the reduction of operating costs.

Real examples of industrial IoT applications

We want to show you here some real examples of IIoT applications in the industry, they can provide you with enough data to understand the importance of Internet of Things in this area:

Caterpillar is among the top industrial IoT companies, it is the world’s largest manufacturer of construction machinery and mining equipment, diesel engines, and industrial gas turbines.

This company has been implementing IoT technologies in their equipment even before people spoke of IoT. Maybe at the beginning, the technology wasn’t advanced, but integrating these technologies was a visionary task.

Doug Oberhelman, CEO of Caterpillar said, “Our vision is that by enhancing our Cat Connect Technology and Services offerings, entire fleets and job sites – every machine, engine, truck, tablet, light tower, smart device, and drone – will eventually share data on one common technology platform and speak the same language.”

Caterpillar has helped many companies save thousands of dollars by connecting machinery to IoT devices and analyzing the data.

How can data be useful? Imagine you are operating a machine at full power, and it has some generators that need to keep the temperature at a low level. This, of course, represents a lot of spent energy and, therefore, more costs. The gathered data can suggest new ways to operate the generator with less energy expenditure and still guarantee the machine’s stability and performance, how? By increasing the amount of generators the machine uses, but operating at a lower intensity; as a result, the operational costs of the machine are reduced.

Amazon, the big online retailer, is using robots to store and handle products inside its warehouses. People may think that it’s better to count on their employees to look for the products on every shelf, however, the experience of Amazon has demonstrated that by using robots, the operating costs have been reduced by 20%.

This way, the employees can save time and do other activities while the robot locates the product for them.

Amazon is also planning to implement a delivery system by using drones. It is an ambitious task, but with the help of IoT and industrial automation, the company will reach a whole new level.

At DeepSea Developments, we built a smart agriculture hub. This device was intended to monitor tractors and other assets. Instead of losing time in unforeseen repairs, the information gathered thanks to the IoT devices allowed the operators to make the necessary adjustments before any problem showed up.

Also, with the IoT devices installed in the tractors, the company would be able to monitor in real time the location of the assets and its trajectory. This helped the people in charge of the crops to improve the routes of the workers and save time by defining better routes for the tractors.