Rapid prototyping has a great benefit, it helps entrepreneurs to speed the time-to-market of their business idea. They can implement iterations fast, and at a low cost. But there are several rapid prototyping methods, and we want to show you which ones they are.

Rapid prototyping is a popular concept nowadays, every entrepreneur, inventor, engineer, and CEO knows what this is. Also they know how important it is to count with this method to build a prototype in a short time.

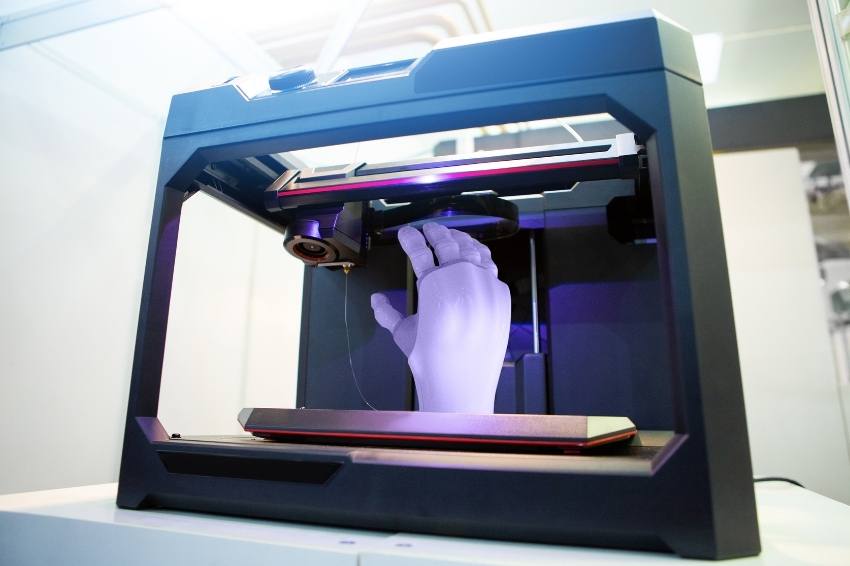

1. 3D printing

This is the rapid prototyping method that made the concept of rapid prototyping popular, that’s why many people think 3D printing is the same as rapid prototyping.

An industrial designer can help you out here to design a 3D model version of your product. This is usually done in a CAD software. Then, the created design will be extracted by the 3D printer for being built.

Pros:

- Flexible design.

- Cost effective.

- Easy to implement.

Cons:

- Not suitable for printing big parts.

- Static cost no matter the amount of printed units.

- It’s not too accurate in the final production.

2. Selective Laser Sintering (SLS)

This is another rapid prototyping method. This is useful for building complex parts; it is done through a sintering process from polymer powder.

However, there are some pros and cons with this type of rapid prototyping.

Pros:

- It is a very cheap process.

- Can produce accurate parts that have complex designs.

Cons:

- The structure may be porous and brittle.

- The prototype may not last long.

3. Fused Deposition Modeling (FDM)

This type of rapid prototyping is also cheap, it can be used by small scale companies. This method uses thermoplastic resin, and the prototype is built layer by layer by melting and extruding the resins.

Pros:

- It can make complex parts.

- Several kinds of plastics can be used.

- It is a very low cost process.

Cons:

- Not suitable for functional testing of prototype.

- It is a slow process.

4. CNC Machining

If you need a prototype, or parts that are functional, accurate, and reliable, you can use this method. CNC Machining controls a range of complex machinery, for example, grinders, lathes, and turning mills. These are used to cut, shape, and create different parts and prototypes.

Pros:

- Different materials can be used: plastic, wood, metal, glass.

- It ‘s very accurate.

Cons:

- It is a little expensive.

- The equipment is not cheap. You may need to hire an external company for the job.

5. Prototype tooling

Also known as Rapid Tooling, this method is used for creating different parts of a prototype with the help of low-cost injection molds. The materials that can be used here are: silicone rubber, soft steel, and aluminum alloy.

Pros:

- More suitable for large pre-production runs.

- You can create a mold with a really low budget.

Cons:

- The mold can’t be used a lot of times depending on the material you choose.

- The created parts are not fully functional or strong.

6. Digital Light Processing (DLP)

This type of rapid prototyping is new in the prototyping world. It uses digital projected light beams. It requires support structures and post-build curing.

Pros:

- The process is really fast.

- The final result is accurate.

- Wide variety of materials.

Cons:

- Parts can degrade if exposed for a long time to the sun.

- It can break or crack with ease.

- It is more expensive than the FDM method.

7. Selective Laser Melting (SLM)

An advanced rapid prototyping method that can create metal parts with a high-powered laser. This method requires a sealed chamber filled with metal powder, and the laser melts the material. Only when the process is done, the new produced part can be retired from the machine.

Pros:

- Can be used for prototyping, and for small scale production.

- Highly accurate in complex designs.

Cons:

- It is expensive.

- The building time is slow due to scanning process.

- Lots of post-processing required

Which rapid prototyping technique is the best?

After all these methods presented above, you may be thinking which one is the best for your project.

We can’t really tell until we know at what stage your project is, your budget, your needs, and the materials you are planning to use; in fact, there are other types of rapid prototyping we didn’t mention in this article.

So, the recommendation here is, think of the goal you want to achieve with the rapid prototyping process:

- Do you want to assemble different parts to build the prototype?

- Do you want to create different versions?

- Is this going to be tested with a specific group of people?

- Do you want to prove its functionality?

- How complex is your design?

- Do you have the budget for several iterations?

By answering these questions, we hope you can get a better insight on what rapid prototyping method adjusts better to your project (see Innovation in IoT).

If you still have questions, and maybe you need to acquire a rapid prototyping service with a reliable prototype company, click below to get in contact with us. You will receive a free consultation.