Learn in this article how to make a prototype by considering different aspects such as: steps to plan your prototype, tools you can use, how much it costs to make a prototype, and estimated times to develop it.

This article will serve as a guide to help you plan your prototype in advance and meet your personal deadlines related to testing, launching it, or getting funding.

Prototype planning

A prototype is an early version of your product, device or platform you want to launch into a specific market. A prototype will be useful for you because it will allow you to test it and get feedback from potential buyers. Let’s see some steps to plan your prototype:

1. Define your idea

Everything starts with an idea, a concept of a product or service you want to provide to others. If your idea isn’t clear, your product won’t be clear. You need to think about this:

- Purpose of my idea.

- What will it look like?

- Are there more competitors in the market?

- Is it original?

- Does it solve a problem of a specific niche?

Answering these questions will help you to narrow your business idea to a specific product or service.

You could for example analyze your competitors, take their products or services and check how they are built. Of course, you won’t copy their designs, but you will try to understand how their products work and if your idea can perform better than theirs.

2. Start designing

An idea sounds good to everyone, but maybe the hardest part is to draw it or conceptualize it in a way people can understand its functionality.

We suggest you start drawing your business idea after you’ve done with step 1. Create sketches of your product or service, trying to show different profiles or features it may have.

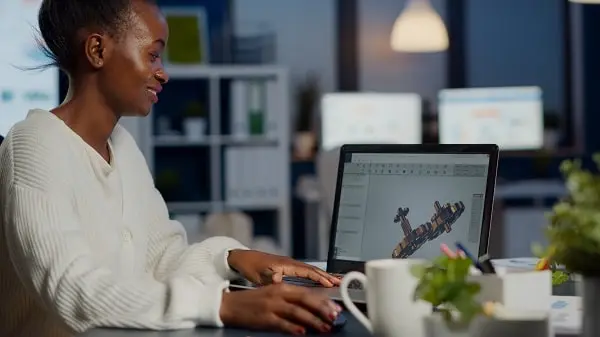

If you have someone that can assist you, or if you have the knowledge, use CAD (Computer Aided Design) software. This is a software tool that allows to create, modify, analyze and optimize blueprints and models in two and three dimensions, and to manipulate simple geometric elements in an easy way.

There are some free CAD software you can use to design your prototype:

FreeCAD: It is free and open source. Whether you are a beginner or professional, you can use this software to design your product.

LibreCAD: This is a 2D modeling software. It is also open source as the previous one. Also, this software allows you to create circuit boards, mathematical figures, and gives you the option to import projects created in softwares like AutoCad.

SketchUp: This 3D model design software is used by many companies in different areas: engineering, video game development, interior design, among others. This is a paid software, however, it offers a free version for students and personal users. This software counts on a big collection of 3D models shared by other users, so you can use them to improve your design.

If you want to go beyond with your prototype, you can hire an industrial designer to help you out. A good industrial product design is crucial to ensure the future success of your product development.

There are many options out there to hire good industrial designers. They can charge you per hour or per project. The main recommendation here is, check their portfolio and their area of expertise, this guarantees they will understand your product with ease.

Now it is time to advance to the next phase, that is, when you start making your prototype as a physical version of your product.

How to make a prototype?

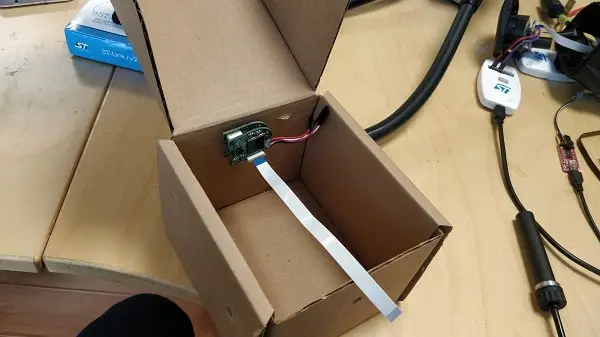

Once you have a sketch, 2D model, or 3D model of your business idea, you can create a handmade version at home. Your creativity will dictate what materials to use (paper, nylon, old clothes, iron, metal, plastic, cardboard boxes). Try to make your prototype with materials that better express the potential functionality of your product.

It doesn’t matter if you don’t have the resources for building something that can be sold in the market, remember that the idea is to create something that appeals to the final version, a low fidelity prototype so good you can convince others to invest in your product.

Before we advance further in the process of making a prototype, it is important to understand what is a low fidelity prototype and a high fidelity prototype.

What is a low fidelity prototype?

It is a basic outline of your product, device, or service. It works as a simple demonstration of functionalities to get some insights from potential customers or investors.

What is a high fidelity prototype?

This kind of prototype is the closest version to the final product that will enter the market. Maybe it’s not fully functional, but the materials, electronic components and design is almost 100% done.

Once you have your low fidelity prototype done you can do the following:

- Show it to potential customers to test its viability and gather feedback.

- Get funding on a crowdfunding website.

- Redesign your prototype according to feedback and improve it by investing in prototype development services.

There are many companies that make prototypes, however, they all have a different level of expertise. You have to analyze the kind of prototype you need to manufacture, and then make a decision on what company to contact. How do you know which service is suitable for making your prototype? Let’s analyze the following:

Industrial design company

You get the service of expert engineers in designing objects, products, devices. If you are in a stage where you only need a render or detailed specifications of how your prototype will look like, you can get this kind of company. Besides, the industrial designers will create your prototype taking into account it may become a physical product someday, so they will give you a detailed design on every piece, mechanics, and functionalities you would need to be able to assemble the prototype.

There are several categories of industrial design: Toys, transportation, footwear, household appliances, electronic products, smart products, and IoT products.

So, analyze which market you fit in, and get a good industrial design company that aligns with your area of interest.

3D printing services

If you want to have a physical version of your idea, you can get prototype 3D printing services. However, bear in mind that 3D prototyping is not going to deliver a fully functional prototype.

3D printing machines use different components to make a product: Silicone, rubber, resin, thermoplastic, metal, among others.

Depending on the materials you use, you will have a prototype that can be useful as a sample to show to potential customers or investors. If you want to go beyond that and improve the design to make it functional, you will have to hire a product design engineer or company to make the proper upgrades, and of course, invest a higher budget in a high fidelity prototype (continue reading to know some costs of making a prototype).

The big pro of 3D printing is that it’s cost effective. You can make hundreds of prototypes at a very affordable price. On the other hand, the biggest disadvantage of this prototyping method is that the printed product won’t have functionality that can be tested by an user. Also, they tend to be fragile.

Prototype tooling

This is another process you can implement for making your prototype. This method, also known as soft tooling or rapid tooling, uses injection molding to print different parts of a prototype. Depending on the mold you use, you may spend between 1,000 dollars and 6,000 dollars.

CNC prototyping

This is another type of rapid prototyping. This method allows you to build a functional version of your product. It can be shown at events and used by different potential early adopters.

The big pro of CNC machining is that the prototype you build is fully functional and can even be used as the final version of your product. However, this method requires a great investment, and expert engineers to handle the prototyping process.

Reasons to refine a prototype

It doesn’t matter which method you use to build your prototype, you will have to make adjustments to it once you can test it yourself, or with other users. Analyze your product and its design or development stage, since this will determine how many adjustments will be needed to be done to the design.

The recommendation here is, collect as much information as you can from your closest friends, family, or potential buyers with a low fidelity prototype, then, when you have a better idea of the adjustments that will be required, invest in a good prototyping process.

Among other reasons that will make you adjust the prototype, there can be a change in the market that affects the technology you are planning to use, like chip scarcity, or on the contrary, a better technology that can reduce the cost of making your product.

If you are building an IoT product, bear in mind they require a lot of updates. If you aknowledge the importance of IoT and the product development phases, you will get outstanding results with your device.

Finally, there can also be problems with the design, people may not like how it feels, or the material may not be of a good quality for long-term use. This could be addressed in future iterations through new product development stages.

How much does prototyping cost?

There are many aspects to consider before contacting prototype makers and requesting a prototype quote that many CEOs, entrepreneurs, and companies don’t take into consideration. If you carefully analyze the prototype manufacturing costs, you will save money on prototyping.

3D prototype model costs

If you are planning to hire an industrial designer to build a 3D model of your project, you can expect to pay rates similar to the following:

- A simple 3D model would cost less than 50 dollars, and it would take over 2 hours to be done.

- A medium complexity 3D model would cost less than 200 dollars, and it would require over 15 hours to be done.

- A high 3D prototype model would cost between 300 dollars and 700 dollars. This would require over 40 hours to be done.

- Finally, a higher level of complexity for the 3D prototype model would cost over 700 dollars, and it would take over 50 hours to be done.

Bear in mind that these rates work as a point of reference; there are aspects to consider like the specialty of the industrial designer, complexity of your design, and requirements.

Costs of making a prototype

As the previous information above, there can be a lot of factors that influence the price of a prototype and that you must take into account before hiring a prototyping company:

- The market for which your product or device is intended: Asian, European, American…

- Patents you need to register; every country has specific requirements and regulations. You will need to comply with the production standards of electronics or design according to the country in which your product will be sold.

- Originality of the product.

- Tax conditions of the country in which the prototype will be made.

- Competitiveness of the market in which you are looking forward to building your product; you won’t get the same price for a project in Asia compared to Europe or America. The wages are different, as well as the cost of access to technologies.

We will give you approximate cost information, according to the stage in which your prototype is:

1. Prototype cost in concept design phase:

This is usually the less expensive phase. If you already have an idea of the product, the prototyping company can help you design your idea with low cost materials such as plastic, cardboard papers, boxes, resin, any material that can be used to mold your prototype and confirm its viability.

Approximate cost in desigh phase: Around Starting at 1,000 dollars.

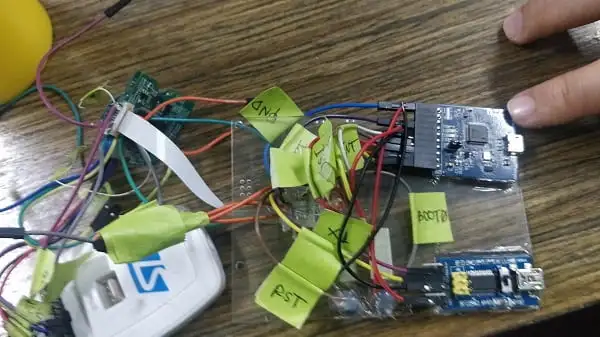

2. Prototype cost in basic engineering phase:

You will have at your disposal an engineering team that will be working on your project. This doesn’t necessarily mean you get a well built product, rather, it can be an electronic board with specific connections and some 3D printed parts to complement the test.

Here a proof of concept is implemented, to confirm whether your design works or not. There can also be the need for a new iteration changing the original design, or the prototyping company may confirm the prototype has potential in this phase and advance to the next one.

Approximate cost of prototype in basic engineering phase: Starting at 5,000 dollars.

3. Soft prototyping cost:

Almost all phases require testing. Since this guarantees the engineers can discover flaws in the design, prototype assembly, or feature limitations.

This phase is more advanced than the one mentioned above. Here you can get a prototype that can be functional (not as a high fidelity prototype) and serves the purpose of testing its performance under different conditions.

Approximate cost of soft prototyping: Starting at 15,000 dollars.

Take into account this phase’s costs vary depending on the complexity of your project; the company will need to print customized parts, get electronic boards, and they will need a specific time (4- 6 weeks) to build the prototype and test it.

4. Detailed engineering cost:

After all tests have been completed, the prototyping company will build the prototype. This time, you get a high fidelity version. Of course, there will be more testing here, but the design is almost fixed, the only things that may vary are the electronic components, embedded firmware, or some details such as material performance and endurance.

Approximate cost: Starting at 25,000 dollars.

Time for this phase may be over 1 month. Remember the complexity of the device will affect the final cost of the prototype.

If you want to manufacture the prototype, that is, to create more versions of it for testing with potential customers or for selling them, the costs may be higher than 25,000 dollars.

If you want to go further, you can take your prototype to the product development phases.

How long does it take to make a prototype?

The specialized company in prototype development will need more or less weeks to make a prototype, according to the development stage in which your project is. Remember every product in each development stage will require different adjustments:

- 3D modeling: Between 1 day and 2 weeks.

- Basic design with paper or cardboard: Between 1 to 2 weeks.

- 3D printed prototype (not functional): Between 1 to 4 weeks.

- A prototype molded in silicone rubber: Between 1 to 6 weeks.

- Prototype of a mobile app or platform: Between 2 to 6 weeks.

- Engineering phase (customized PCB and electronics): Between 5 to 13 weeks.

- Soft prototyping: Between 5 to 9 weeks.

We hope this information is useful for you. Entrepreneurs and startups need the product development process to advance. And with the information provided above, you can get a better idea of how much time you may take to build your prototype, and the necessary budget.

At DeepSea Developments, we have helped clients in over 4 countries to design and develop prototypes through outsourced product development services. We have been recognized as top 1 leaders in IoT, and hardware and software development. If you have any questions regarding your prototype or you need a free consultation, contact us by clicking below. Our super creative engineering team will be willing to help you with your project requirements.