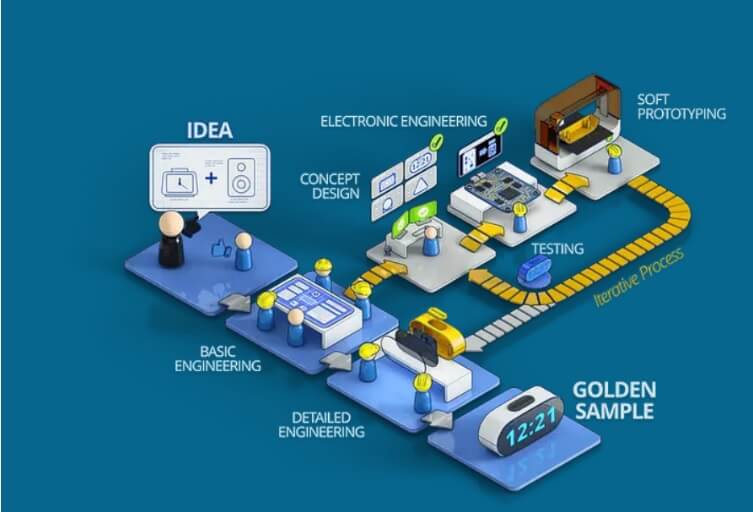

All products you have seen in the market have gone through hardware prototyping, this means you can’t launch a new product without carrying out this process. We will tell you in this article why prototyping is important, the different hardware prototypes you can get, and what tools you may need for that.

Why is a hardware prototype important?

You have a great business idea, and you want to make it a reality. Will you go straight to the manufacturing process? That’s not a good idea, not at all.

This is where hardware prototyping comes in. When you build a prototype of your product or device, you guarantee at least three things: you reduce the risk of failing in the market by testing your idea, the great quality of the final product, and potential investment from people interested in your business idea.

Do you know why hardware design and development is so important? Because the different processes carried out guarantee the success of your product; at least at a technical level.

The products you use such as phones, wearables, headphones, and laptops have been through hardware prototyping processes. The companies that produce them don’t take the risk of launching a product without proper testing and iterations; until they get the final result suitable for the market.

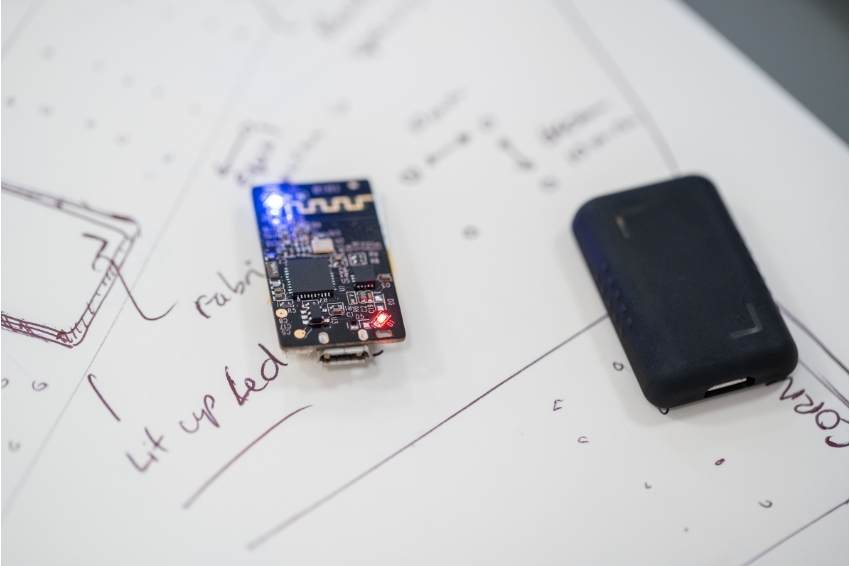

Your business idea will also go through prototyping phases, and that will help you develop a great product (See prototype example).

Different hardware prototypes you can get

You may wonder, what kind of hardware prototype do I need? Well, it depends on what stage your business idea is. Prototype makers can offer you several options:

1. I just have an idea

Let’s say you have an idea for a consumer electronics product, maybe a smart bottle, keyboard, wearable, or IoT device for daily use at home.

We love ideas, and to make them a reality. And surely you want to do the same, but first, it is necessary to test your idea, that is, to validate its technical feasibility.

The hardware prototyping here will be the most basic possible: using a standard development board (Arduino or Raspberry Pi), cardboard papers, plastic, lego figures, boxes, or clay. Any material that allows you to sketch a basic model of how your product would look like.

This phase of hardware prototyping will be the beginning of your project, and you will be able to find out if this product has potential.

Pros:

- The time for testing is fast.

- Cheap materials for the prototype.

- Multiple iterations can be made at a low cost.

Cons:

- The most complex features of the product can’t be tested.

- Limitations in design.

- Not suitable for potential customers or investors.

2. I need basic engineering

This phase of the hardware prototyping process will go deeper than the previous one. Here it is necessary to pay more attention to hardware design and electronics (see hardware product management).

You need to build a custom PCB (Printed Circuit Board) with the help of electronics prototyping service that will allow you to test the features you want to include in your product. You may also need welding machines, microcontrollers, plastic, and cutting tools.

The basic engineering phase is necessary because you need to test the functionality of your product at a low scale. If you decide to go mass production, you need to have all necessary components identified for guaranteeing the production costs will be affordable.

Pros:

- This hardware prototype gives you more direction regarding your business idea.

- Quick testing.

- Tools and materials are not too expensive.

Cons:

- It requires basic knowledge of electronics.

- Some features may require the assistance of firmware developers.

3. I need soft prototyping

This stage of the hardware design process will take your product to a more recognizable phase, that is, you get a physical version of your product.

It may start with an industrial design (3D modeling), and from there, a quick prototyping process may be carried out.

There are different types of soft prototyping: 3D printing, prototype tooling, Fused Deposition Modelling (FDM), binder Jetting, Selective Laser Sintering (SLS), and CNC machining.

All these processes require different materials and time for being carried out. Also, it is necessary to mention that 3D printing is the most popular process for soft prototyping.

Pros:

- Quick testing with potential customers.

- Evaluation of aesthetics and ergonomics.

- New iterations can be performed.

- It could be shown to potential investors.

Cons:

- The printed version may be expensive depending on the materials you need: silicone rubber, aluminum alloy, a combination of steel and aluminum, among others.

- You need the assistance of an industrial designer for the 3D model of your product.

- You need a 3D printing machine.

4. I need a finished hardware prototype

This is where you get the closest version to the final product. This hardware prototyping phase gives you as a result a golden sample; that is, the prototype version that could be your MVP (Minimum Viable Product).

You can test your MVP for implementing adjustments, or start selling it in the market, and attract early adopters. Another strategy is to convince investors to fund your project, and go from this golden sample version to the manufacturing process.

Remember that every phase of the hardware prototyping process requires iterations. For getting the golden sample, many iterations must be carried out until there is a finished hardware prototype that complies with the following:

- Engineering validation tests.

- Validation of the design.

- Validation of the final product.

Pros:

- You get a hardware prototype ready for the market.

- Finished design, and well-built-in electronics.

Cons:

- You need a specialized engineering team for this phase.

- You need advanced tools, materials, and machines.

- This stage requires a high budget.

If you have the knowledge for completing the hardware prototype, fantastic! If not, you can think of outsourcing product development services.

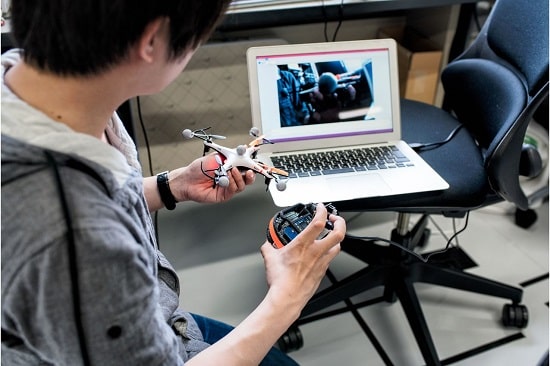

Necessary tools for hardware prototyping

Finally, we want to mention some tools needed for hardware prototyping. This process is more accessible today than it was years before. Due to advances in technology, like cheaper 3D printing machines, and great 3D modeling software, it is possible to design and build hardware prototypes with ease.

- 3D printing machines allow you to build several prototypes with different materials.

- 3D CAD software for designing parts of a prototype, or the full product for posterior development with 3D printing machines or more advanced tools.

- Standard enclosures for your electronic components, you may need to get these for testing your hardware under different conditions.

- Arduino. Use this as a way to test your hardware prototype through a standard PCB and its corresponding software. This tool is great for any kind of hardware prototyping, no matter the complexity.

We hope this quick guide serves you as a way to design, test and develop your hardware prototype. Remember the success of the process depends on what stage your product is, and how far you want to take it.

Our engineering team has been working on hardware prototyping for entrepreneurs and startups in over 4 countries. DeepSea Developments provides cutting-edge development services and our customers are happy with the results.