A lot of startups and CEOs have trouble grasping the concept of Hardware Design. They often confuse it with PCB Design and end up asking questions like “Can you design a PCB (Printed Circuit Board) for my drone?”, however, what they actually would have to ask is, “Can you create the hardware for my device with the features I need?”

This is a common issue that many clients that have come to DeepSea Developments manifest when they are looking for an engineering team to help them out.

Definition of hardware design

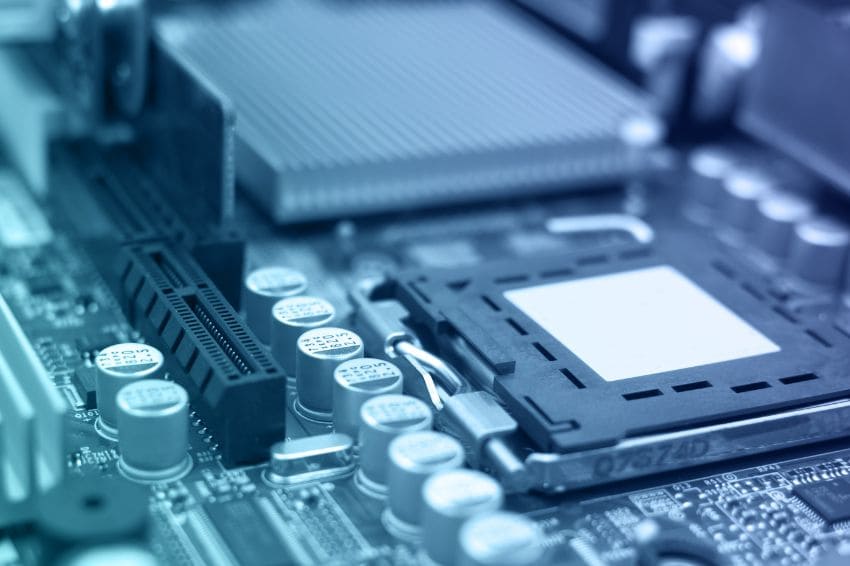

Hardware design is the process of creating and testing physical components that make up electronic devices. It involves the design and development of computer hardware components, including circuit boards, microchips, schematics, and scanners, as well as the creation of the physical parts of a product, such as processors and sensors. The hardware design process typically includes researching, developing concepts, creating schematics, prototyping, and testing to ensure accuracy.

Additionally, hardware designers are often involved in the manufacturing and installation process, they must have a deep understanding of electronic circuits to face any technical challenge that shows up. Popular products of hardware design include computer motherboards, mobile circuit boards, and video game boards. Hardware design is a crucial component of the product development process that enables the creation of functional and efficient electronic devices.

Hardware design can be broadly divided into two categories: digital hardware design and analog hardware design. Digital hardware design involves the creation of digital circuits and systems that process binary data, such as microprocessors, memory chips, and digital signal processors.

On the other hand, analog hardware design involves the creation of analog circuits and systems that process continuously varying signals, such as amplifiers, filters, and power management circuits. In this case, several aspects have to be considered, such as noise, distortion, and signal attenuation.

Both digital and analog hardware design are essential for the creation of complex electronic products. This is what makes hardware design services so important, since startups and CEOs can get a great product with this.

In order to guarantee a good hardware design process, you need a great team that has expertise in different areas: electrical engineering, computer engineering, mechanical engineering, and materials science.

Difference between hardware design and PCB design

As we mentioned above, many clients get confused with hardware design and PCB design (See PCB benefits), these concepts are part of electronic product development, that’s why they are closely related.

Remember that hardware design refers to the process of designing and developing the physical components that make up electronic devices, including processors, sensors (see IoT sensors), and circuit boards.

On the other hand, PCB design is a specific subset of hardware design that focuses on the design and layout of the printed circuit board. A PCB is a board that holds and connects electronic components using conductive pathways (see PCB prototyping). Depending on the project you are planning to build, there will be different types of PCBs that you need to use to ensure the proper functioning of your device, hardware, or IoT product (why is IoT important).

Hardware design process

The hardware design process starts with outlining the specifications or requirements of the project. This may include features and system requirements.

Then it is necessary to advance to the feasibility analysis. Where a proof of concept will be carried out to confirm your business idea is possible and can provide results in the market.

From this point, there will be a preliminary hardware design, which will consist of outlining electronic functions and connections. Let’s say, microcontroller, displays, sensors, chips, and all necessary connections to make the hardware work.

Then, the schematic circuit diagram design will come. We usually use Altium or KiCad. Bear in mind the PCB design needs a lot of work, depending on the complexity of the device.

As a result from this electronic hardware design, the engineers will create the Bill of Materials (BOM), which is a shopping list of all the mechanical and electronic components (detailed by quantity and specifications) you need to get for start building your product.

Example of hardware design

We like to use examples in our articles to explain different concepts better. Let’s take a popular device to understand hardware design, a smartphone. This device has several components:

- CPU

- Battery

- Lenses

- Sensors

- Microprocessors

- Microcontrollers (ESP32 chip)

- Screen

Each one of these components is designed and developed separately by teams of engineers, who work together to create a cohesive device that functions optimally.

Once all of these components are built, it will be necessary to work on firmware and software. This will ensure that the different electronic components will be able to integrate together, gather information, and work as a whole to deliver a great experience to the user that will buy the phone.

Creating a product or device from scratch involves many steps and requirements to be met. If you already have advanced in hardware design (how does the design of hardware work), you could go to a new stage, which is prototyping.

You can read more about prototyping in the following articles: